DCV – the single largest energy efficiency opportunity

Using demand control ventilation (DCV) or demand-based control (DBC) to safely adjust ventilation rates can reduce HVAC energy costs by 40-60% in laboratory spaces, and 10-30% in non-laboratory areas. Implementing solutions for air-side reductions can be the most significant energy efficiency measure for your building (no wonder it is now required by the NYS Energy Conservation Code!). However, according to the Department of Energy (DOE), one of the problems with demand control ventilation is the relatively high life cycle costs associated with maintaining the sensors. This requirement significantly reduces net energy savings. Numerous studies have proven that CO2 sensors drift significantly over time and thus create havoc with control strategies that either aim to save energy or assure good indoor air quality1. The DOE further maintains that even so called ‘self- calibrating’ sensors drift and typically fall into a replacement time frame of four years – making it easy to see why CO2 sensor-based DCV systems not been widely implemented. In our experience, most facilities skip maintenance and eventually disconnect the sensors. Our advice: If you don’t plan to calibrate or maintain sensors, don’t install them.

Game changing technology

Centralized sensing platforms for demand control ventilation significantly optimize outside air quantities in buildings and improve occupant safety. Centralized sensing platforms use tubing to transport air samples back to one sensor (e.g. CO2), or a common set of sensors (e.g., CO2, TVOC, Particles, Dew Point, CO). Simply stated, maintaining one sensor, or one set of sensors, is much easier and significantly less costly than maintaining 30-60 or more discrete sensors throughout multiple rooms. With a centralized platform, sensors stay accurate through regular calibration; they are simply swapped out every six months as part of an annual service program. If sensors are being relied upon for control decisions, they must stay accurate – or chances are you will waste energy. A centralized sensing platform provides a far more practical and affordable solution.

In laboratory buildings, 50-70% of energy costs are related to heating, cooling, and distributing 100% outside air. Along with improved lab DCV solutions, significant changes in lab guidelines and standards allow for both deep energy reductions and improved lab safety and operations2.

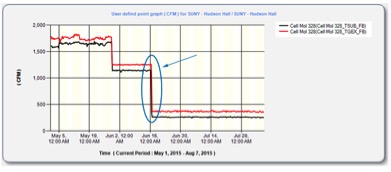

These systems readily enable the use of dashblock information, which may be arranged by users to present a broad spectrum of IEQ, ventilation, and comfort information in a concise visual display.

Shown above: Typical lab room showing exhaust (red) and supply flow (black) reductions from pre-OptiNet levels in May. Initial reductions did not meet anticipated target level, until after VAV actuator was repaired on June 16th. (SUNY Plattsburgh-Hudson Hall Case Study).