Project info:

Efficiency Measure:

Type:

Client:

Engineering Design:

Building:

Key Results:

DESCRIPTION

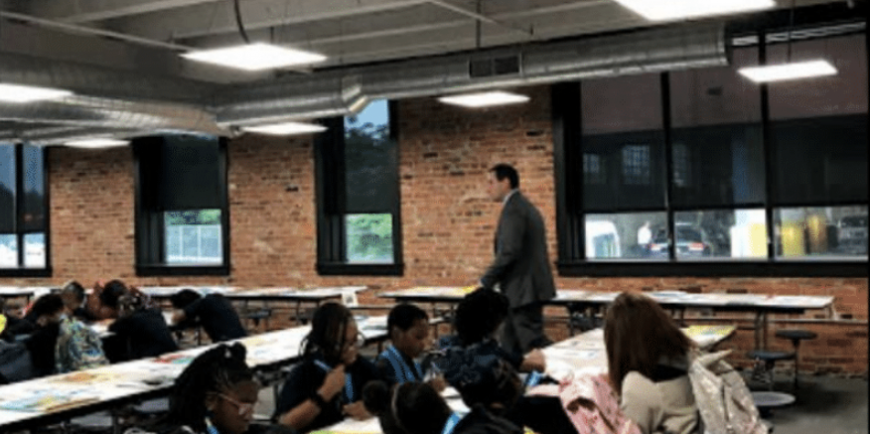

Buffalo Collegiate Charter School is a tuition-free public charter school in Buffalo, NY and is a member of the SUNY Charter Schools Institute. Having opened the doors in August of 2018 with grades 4 and 5, they will add one grade every year until they have a fully-enrolled 4 through 12 school in 2025. Their teachers and staff are a mission-driven team committed to ensuring that Buffalo’s resurgence reaches all members of the city – especially the children.

The project developers, Tri-Main, began the gut rehab of the 42,500 square foot free-standing concrete and brick building in 2017. The initial HVAC plan for 12 RTU’s included automated controls. However, due to budget overruns the automation was value-engineered out. However, the team at Green Building Partners met with the Tri-Main developers and proposed an alternate wireless automation system that would replace the conventional lighting and HVAC control system for a fraction of the price. Both the electrical and HVAC contractors purchased the various wireless automation components directly from Intellastar.

The Intellastar wireless automation platform provided the following benefits:

- Significantly reduced first cost, especially for lighting control (est. 50% savings)

- Par automation functionality (as compared to conventional control platform)

- Ability to cost effectively roll in HVAC automation on the same platform as lighting, thus garnering National Grid incentives for Energy Management System.

The Intellastar wireless control system enabled significant savings due to:

- Light switches and occupancy sensors (wireless & battery-less) saved labor and material cost of wiring in conduit

- Centralized lighting controls, i.e. one controller vs. a controller in each room.

- Thermostats communicated wirelessly to gateway control providing various energy management measures, including centralized programming of night, holiday, weekend, and unoccupied set back.

The schematic drawings comparing the conventional wired vs. wireless solutions are shown in this linked document.

After the project was completed, Tri-Main approached Green Building Partners to determine the best way to submeter this building for actual electric use so they could provide an accurate charge to the school. The submetering was added at a relatively low cost due to the fact the Intellastar automation platform was also able to provide the gateway functionality for the submetering. Minor modifications were made to the Ethernet communication infrastructure to accommodate the submetering.